Cold forging hydraulic press

|

|

|

|

|

|

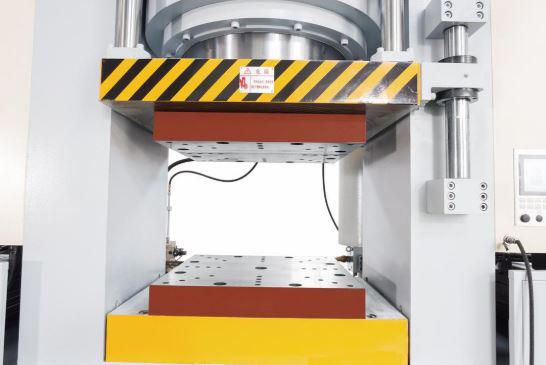

Touch screen |

Worktable |

Application

|

|

5000T cold forging hydraulic press, mainly be used for induction bottom pot, non-stick pot. Under pressure, press two metals together. The double-bottomed pot contacts the heat source layer and transfers heat quickly, which can make the heat and temperature distribution uniform. The layer inside the pot is smooth, wear-resistant, not easy to rust, and will not produce compounds harmful to human health

Key Features

1. The frame are welded frame structure, the force condition is reasonable, the design safety factor is high, and the service life can reach more than 15 years.

2. Under full load, the table deformation is only 0. 5~1mm/m, ensuring high precision suppression.

3. The main cylinder adopts the international advanced anti-leakage composite sealing technology and metal expansion ring sealing technology, which can greatly improve the reliable life of the cylinder seal.

4. The cylinder piston adopts advanced composite bimetal welding technology, which improves the wear resistance and reliable life of the cylinder, and the service life can reach more than 30,000,000 times.

5. Fast cylinder technology can realize no power and rapid down, improve work efficiency and save energy.

6. The servo oil pump system combines the fast stepless speed regulation characteristics of the servo motor and the self-regulating oil pressure characteristics of the hydraulic oil pump, which brings huge energy saving potential, and the energy saving rate can reach up to 30%-80%.

Data Sheet

|

No |

Name |

Parameter |

||

|

1 |

Model |

Yz61-5000T |

||

|

2 |

Nominal force |

50000KN |

||

|

3 |

Working pressure of hydraulics, Mpa |

80 |

||

|

4 |

Press plate material |

Steel |

||

|

5 |

Main cylinder stroke |

350mm |

||

|

6 |

Daylight |

1100mm |

||

|

7 |

Main Cylinder qty |

1 |

||

|

8 |

Frame type |

Frame structure |

||

|

9 |

Ejection Cylinder Force |

500KN |

||

|

10 |

Ejection Stroke | 0~350mm | ||

|

11 |

Servo motor |

60*3 |

||

|

12 |

Maximum speed plate lifting |

200mm/sec |

||

|

13 |

Plate closing speed |

200 mm/sec |

||

|

14 |

Plate working speed |

4.8-19mm/sec |

||

|

15 |

Weight of machine |

70 Ton |

||

|

16 |

Worktable size |

L-R |

1250mm |

|

|

F-B |

1250mm |

|||

|

17 |

Dimensions |

LR |

3380 |

|

|

FB |

1980 |

|||

|

H |

4390 |

|||

Structural Components

●The hydraulic press machine has built-up type frame structure and is comprised of a main machine and a control mechanism. The equipment consists of a whole frame, electrical system, hydraulic system.

●The control mechanism is comprised of a hydraulic system, an electrical control system, a stroke limiting device, pipelines, an electrical control box and other auxiliary parts. The electrical system and the hydraulic station are connected into one via oil pipes and lead wires to realize the procedure of whole actions.

●The main body of the slide is #45 steel whole plate. The bottom plate of the slide is a whole steel plate ensuring sufficient rigidity and strength. The guidance of the slide is sideling wedge style with foursquare and eight friction faces guide rail, which gives high precision and rigidity. After adjustment, no precision difference occurs, precision is well kept and the load-deflection resistance capacity is strong, ensuring slide operation precision, that the slide can withstand a large eccentric load and that the slide operates smoothly without chatter. The guide rail beside slide is made by copper-base alloy, adopt bow-shape oil slot structure to make sure guide rail oil no leaking, increase anti-wearing ability of the slide. On the guide rail there are special deisgned oil filling holes for auto oil-filling, beneath there are oil recieve box to avoid oil stain the floor.

Hydraulic Control System

●The hydraulic control system is mainly placed side of equipment, where been designed maintainess platform, has tidy appearance and is easy to maintain. The hydraulic system is comprised of an oil tank, a hydraulic main control system, a pump station, a pressure gauge, a strainer and other accessories. They are connected into a whole hydraulic control system mainly via pipelines.

●The hydraulic system is mainly characterized by proportional and servo close-loop control, dual support protection control, etc.

●Oil tank been set forced cooling filtering system(industrial plate-type water cooling device, cooling by circulating water, oil temperature≤55℃,make sure machine can steadily pressing in 24 hours.) to ensure oil temperature been controlled in allowed range. Oil temperature warning type: oil up to 40℃, temperature alert appears on touchscreen, forced cooling system automatic working. Oil up to 55℃, motor shut down, operation stop, temperature alert appears on touchscreen.

●The pressure of slide is regulated by using a proportional pressure valve and a manual remotely regulated pressure valve; 2 mode can be switch freely. (An acceleration and deceleration device for servo control pressure and flow fluctuation is installed in the system, which can better improve pressure control stability.) The pressure at the proportional regulation mode is set and displayed directly on the touch screen. The pressure display precision is 0.1Mpa, and the pressure control precision is less than ±0.3Mpa.

Servo System

Servo System Composition

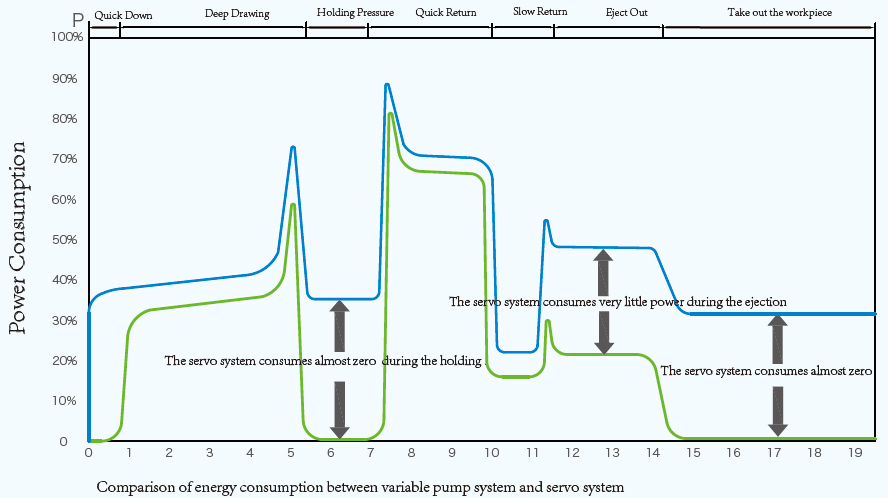

Energy saving

Compared with the traditional variable pump system, the servo oil pump system combines the fast stepless speed regulation characteristics of the servo motor and the self-regulating oil pressure characteristics of the hydraulic oil pump, which brings huge energy saving potential, and the energy saving rate can reach up to 30%-80%.

Servo System

Photo-Electrical Safety Guard Front & Rear

Two Hand Operation Stand

Lock nuts are provided for movable parts

Hydraulic Support Insurance Circuit

Overload Protection: Safety Valve

Liquid Level Alarm: Oil level

Oil temperature Warning